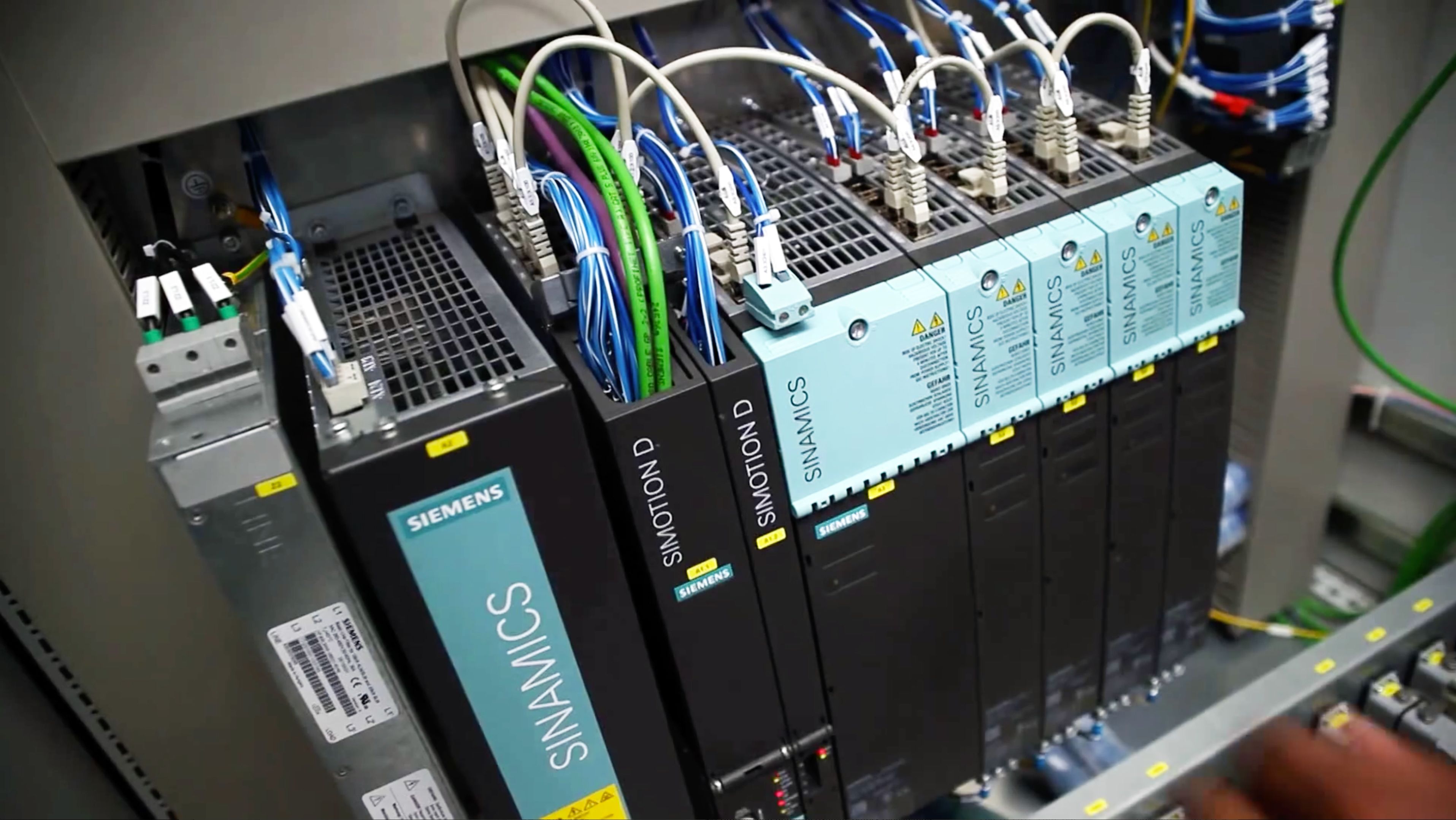

Product Details

he SINAMICS S120 drive system is a modular, high-performance drive designed for a wide range of industrial applications, including machine building, CNC machine tools, and more. It offers flexibility and scalability, allowing for single-axis and multi-axis drives, distributed drives, and integrated motion control functions. The S120 is known for its precise speed and torque control, integrated safety features, and a variety of communication options. Key Features and Functionality: Modular Design: The S120 is built on a modular architecture, with components like Line Modules, Motor Modules, and Control Units that can be combined to create customized solutions. Multi-axis Control: It supports multi-axis drives, enabling synchronized motion control of multiple motors. Integrated Safety Functions: SINAMICS S120 includes integrated safety features like STO, SBC, SS1, SS2, and others, ensuring compliance with safety standards. Regulated Infeed/Regenerative Feedback: These features allow for energy recovery and stability against supply fluctuations. Communication Options: The S120 offers various communication options, including PROFIBUS DP, PROFINET, and DRIVE-CLiQ, for integration with other automation systems. High Dynamic Performance: The S120 provides excellent dynamic performance, making it suitable for applications requiring fast and precise movement. Applications: The S120 finds use in various industries, including packaging, plastics, textile, printing, CNC machine tools, and more. SINAMICS S120 Combi: This is a compact and rugged drive system specifically designed for compact turning and milling machines. It integrates a line infeed, regenerative feedback, and Motor Modules for spindle and feed motors within a single Power Module. It offers a smaller footprint and lower energy requirements.